What are the key components of a mechanical torque wrench, and how do they function together to achieve torque measurement and application?

A mechanical torque wrench is a precision tool designed to apply a specific amount of torque to a fastener or object. It consists of several key components that work together to achieve accurate torque measurement and application.

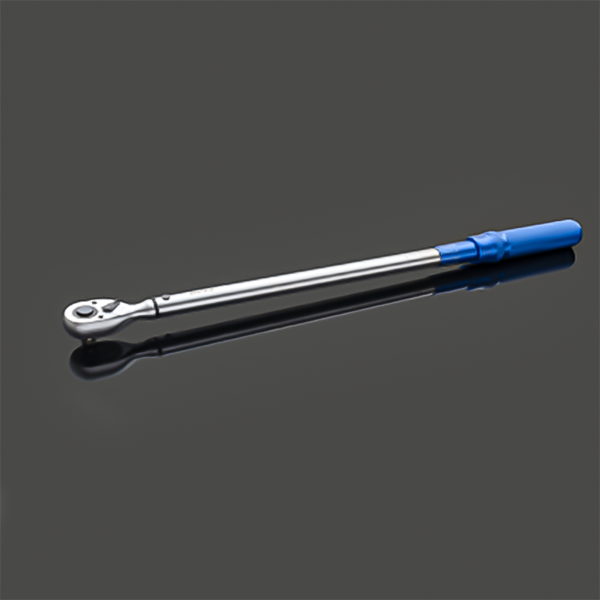

The handle is the part of the wrench that the user holds. It provides a comfortable grip and allows the user to apply torque to the fastener. The handle may be straight or angled, depending on the wrench design.

The shaft connects the handle to the head of the wrench and serves as the lever arm through which torque is applied. It transmits the force from the user to the fastener.

The head of the torque wrench is the part that comes into contact with the fastener or nut. It contains the mechanism responsible for measuring and indicating torque. There are various types of heads, such as the ratcheting head, which allows for rotation in one direction while holding the torque setting.

The torque indicator is an essential part of the mechanical torque wrench and provides a means of measuring and indicating the applied torque. There are different types of indicators, including:

Beam-type torque wrenches have a calibrated beam that deflects when torque is applied. The user reads the torque value on a scale as the beam bends.

Click-type torque wrenches emit an audible click or produce a tactile sensation when the preset torque level is reached. This alerts the user to stop applying force.

Dial-type torque wrenches have a circular dial or gauge that displays the applied torque in real-time as the user applies force.

This component allows the user to set the desired torque value before applying force. The mechanism typically involves a knob or collar that can be turned to adjust the torque setting.

Some torque wrenches have a locking mechanism to secure the torque setting and prevent unintentional adjustments during use.

In operation, the user selects the desired torque value by adjusting the torque adjustment mechanism. When the wrench is applied to a fastener, the shaft and head work together to transmit the user's force to the fastener. The torque indicator, depending on the type of wrench, will provide feedback to the user when the preset torque level is reached. This feedback can be visual (dial-type), auditory (click-type), or tactile (click-type and beam-type). When the indicator signals that the preset torque has been achieved, the user stops applying force, ensuring that the fastener is tightened to the specified torque value.

Can you explain the principle behind the operation of a mechanical torque wrench and how it ensures accurate torque values?

The operation of a mechanical torque wrench is based on a fundamental principle of elastic deformation, typically involving a calibrated spring or other mechanisms.

Mechanical torque wrenches operate on the principle of elastic deformation, specifically in the case of a calibrated spring within the wrench. When torque is applied to a fastener using the wrench, the calibrated spring or mechanism undergoes elastic deformation, meaning it temporarily changes shape under the applied force.

Before a mechanical torque wrench is used, it undergoes a precise calibration process. During calibration, the wrench is subjected to a known torque, and the deformation of the internal spring or mechanism is measured and recorded. This process establishes a relationship between the applied torque and the deformation of the spring.

The wrench is equipped with a torque indicator, which could be a scale (beam-type), a clicking mechanism (click-type), or a dial (dial-type). The torque indicator is connected to the calibrated spring or mechanism.

To use the wrench, the operator sets the desired torque value using an adjustable mechanism on the wrench, often a knob or collar. This setting determines how much torque is required for the spring to deform to a certain extent.

When the wrench is used to tighten a fastener, the operator applies force to the wrench handle. This force is transmitted through the wrench's shaft and head to the fastener.

As the operator applies force, the calibrated spring or mechanism within the wrench undergoes elastic deformation. The deformation is proportional to the applied torque, as determined during the calibration process. When the applied torque reaches the preset torque setting, the spring or mechanism deforms by the calibrated amount.

In summary, a mechanical torque wrench operates by using a calibrated spring or mechanism to measure the deformation caused by an applied torque. The wrench is calibrated to establish a precise relationship between deformation and torque, ensuring that the user can accurately tighten fasteners to a predetermined torque value, thereby preventing over-tightening or under-tightening in various industrial applications.